Beijing Misnco Control Technology Co., Ltd.

Tel:010-61805655

Email: misnco@163.com

Office address: Room 202, building 28, Haite garden, Shijingshan District, Beijing

Production base: 1f, building 6, District 1, future science and Technology City, 165 Yuxiang street, Luancheng District, Shijiazhuang City, Hebei Province

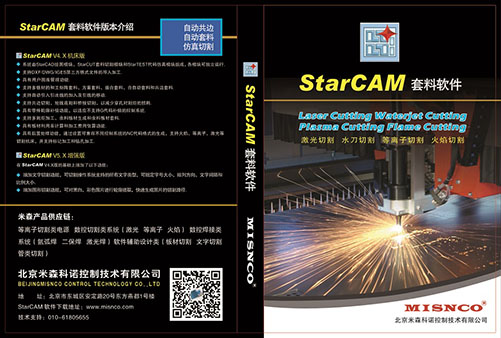

Laser/plasma/flame cutting nesting software STARCAM

StarCAMV4. X Machine Edition

1. The system consists of StarCAD drawing module StarCUT nesting cutting module and StarTEST code simulation module, each module can be operated independently

2. Support the import and processing of DXF/DWG/IGES third-party format files

3. Has the function of user gallery management

4. Support multi-plate and matrix nesting scheme nesting combination nesting automatic nesting and common edge nesting

5. Support automatic introduction of the addition of pinouts and the movement of leads

6. Support co-edge cutting short line continuous cutting and bridging cutting to reduce the loss of perforation to the torch

7. Has part contour compensation function to adapt to control systems that do not support G code compensation

8. Support multi-torch processing of residual sheet generation and residual sheet nesting

9. It has the function of plate utilization rate calculation and processing cost estimation

10. With post-processing function by setting the generation of NC code formats that can be compatible with different control systems 11.Supports cutting machine tools such as flame plasma laser and supports marking processing and drilling processing